Villanova University Unveils Groundbreaking Isothermal Compression System for Enhanced Energy Storage

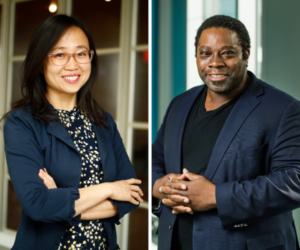

VILLANOVA, Pa. (March 3, 2025)—Innovative strides in energy storage technology have been made by Sylvie Lorente, PhD, Associate Dean for Research and Innovation and the William M. Brown ’84, ’87 Endowed Chair in Mechanical Engineering at Villanova University. She recently secured a patent for an isothermal compression system that maintains air temperatures constant during compression and expansion.

In collaboration with Adrian Bejan, PhD, J.A. Jones Distinguished Professor of Mechanical Engineering at Duke University, Dr. Lorente developed a solution aimed at optimizing compressed air energy storage (CAES). Their innovation addresses the inefficiencies of traditional systems, where temperature shifts necessitate extra energy, impacting overall efficiency.

According to Amanda Grannas, PhD, Vice Provost, Chief Research Officer, and professor of Chemistry at Villanova University, “This novel compressed air energy storage system will provide an efficient and cost-effective solution for the renewable energy industry. We look forward to the development of this product and are excited to see how it transforms current renewable energy systems around the world.”

Traditional methods often depend on external devices for temperature control, but the new design by Drs. Lorente and Bejan features a phase change material incorporated directly into the compression chamber. This material, akin to wax, transitions from solid to liquid with heat absorption. It efficiently stabilizes temperature by absorbing heat during compression and releasing it during expansion.

Dr. Lorente emphasized the importance of energy storage, stating, “Renewable energy sources, like wind or solar power, are not always available when they are needed. Conversely, there are occasional surpluses of energy that cannot all be used at once. The chamber we designed can compress that energy in gas form for storage, and then expand the gas when it is needed, keeping the process as streamlined and effective as possible.”

The phase change materials are designed with a dendritic structure, resembling tree branches, to enhance airflow and reduce resistance, thereby increasing the system’s efficiency. Moreover, the size of these materials can be tailored to suit specific applications.

The development of this CAES system spanned two years, involving comprehensive theoretical analysis and numerical modeling of the chamber and materials. With the patent secured, efforts will now focus on constructing a prototype to advance this promising technology towards real-world application.

Read More Here